|

Heat Sink Performance Calculator

|

|

|

Forced Convection

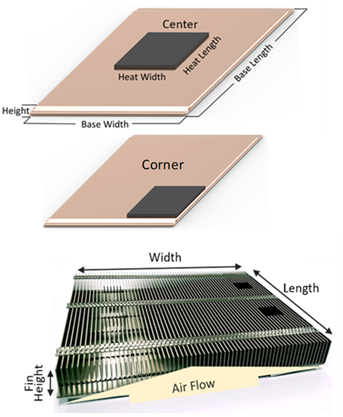

Fin Pack with Solid Metal or Vapor Chamber Base

|

|

|

|

|

|

|

|

|

|

|

Design Tips

|

|

|

|

|

|

|

|

|

1.

Length - up to 500mm

|

|

|

|

|

|

|

|

2.

Fin Thickness - ranges from 0.2-0.6mm

|

|

|

|

|

|

|

3.

Fin Spacing - should be at least 2X the fin thickness

|

|

|

|

|

|

|

4.

Fin Height - between 3-100mm. Watch fin efficency - don't make the fins

taller than useful.

|

|

|

|

5.

Materials - aluminum or copper. Both can be nickel plated for corrosion

resistance.

|

|

|

|

6.

Vapor chamber - copper/water/sintered wick

|

|

|

|

|

|

|

Notes

- Airflow in this model assumes zero bypass.

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

Inputs (in yellow)

|

|

|

|

|

|

|

|

|

Heat Source Info

|

|

|

|

|

|

|

|

|

Power (Q)

|

|

Watts

|

|

|

|

|

|

|

Heat Source Length

|

|

mm

|

|

|

|

|

|

|

Heat Source Width

|

|

mm

|

|

|

|

|

|

|

Heat Source Location

|

|

Center or Corner

|

|

|

|

|

|

Heat Source Area

|

|

cm2

|

|

|

|

|

|

|

Power Density

|

|

W/cm2

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

Heat Sink Base Info

|

|

|

|

|

|

|

|

|

Base Length

|

|

mm

|

|

|

|

|

|

|

Base Width (Standard)

|

|

mm

|

|

|

|

|

|

|

Material (Metal Base)

|

|

Aluminum or Copper

|

|

|

|

|

|

Base Thickness

|

|

mm (VC & Metal Base)

|

|

|

|

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

Fin Pack Info

|

|

|

|

|

|

|

|

|

Fin Height

|

|

mm

|

|

|

|

|

|

|

Fin Thickness

|

|

mm

|

|

|

|

|

|

|

Fin Gap

|

|

mm

|

|

|

|

|

|

|

Air Flow

|

|

CFM

|

|

|

|

|

|

|

Fin Material

|

|

Aluminum or Copper

|

|

|

|

|

|

Ambient Temperature

|

|

|

|

|

|

|

|

|

Fin Efficiency

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

TIM

|

|

|

|

|

|

|

|

|

Interface Material

|

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

Results

|

|

|

|

|

|

|

|

|

Air ∆T

|

|

°C

|

|

|

|

|

|

|

Fin to Air ∆T

|

|

°C

|

|

|

|

|

|

|

Fin ∆T

|

|

°C

|

|

|

|

|

|

|

Total Fin Pack ∆T

|

|

°C

|

|

|

|

|

|

|

Fin Pack Rth

|

|

°C/W

|

|

|

|

|

|

|

|

|

" H2O

|

|

|

|

|

|

|

|

PA

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

TIM ∆T

|

|

°C

|

|

|

|

|

|

|

Base - Fin ∆T

|

|

°C

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Vapor Chamber

|

Metal Base

|

|

|

|

|

|

|

Base ∆T

|

|

|

°C

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

Total Heat SInk ∆T

|

|

|

°C

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

Thermal

|

|

|

|

|

|

|

|

|

Conductivity

|

|

w/mk

|

|

|

|

|

|

| |

Across the length of the VC

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

|